High to Low Volume Manufacturing of Custom Cable Wire Harnesses & Assemblies

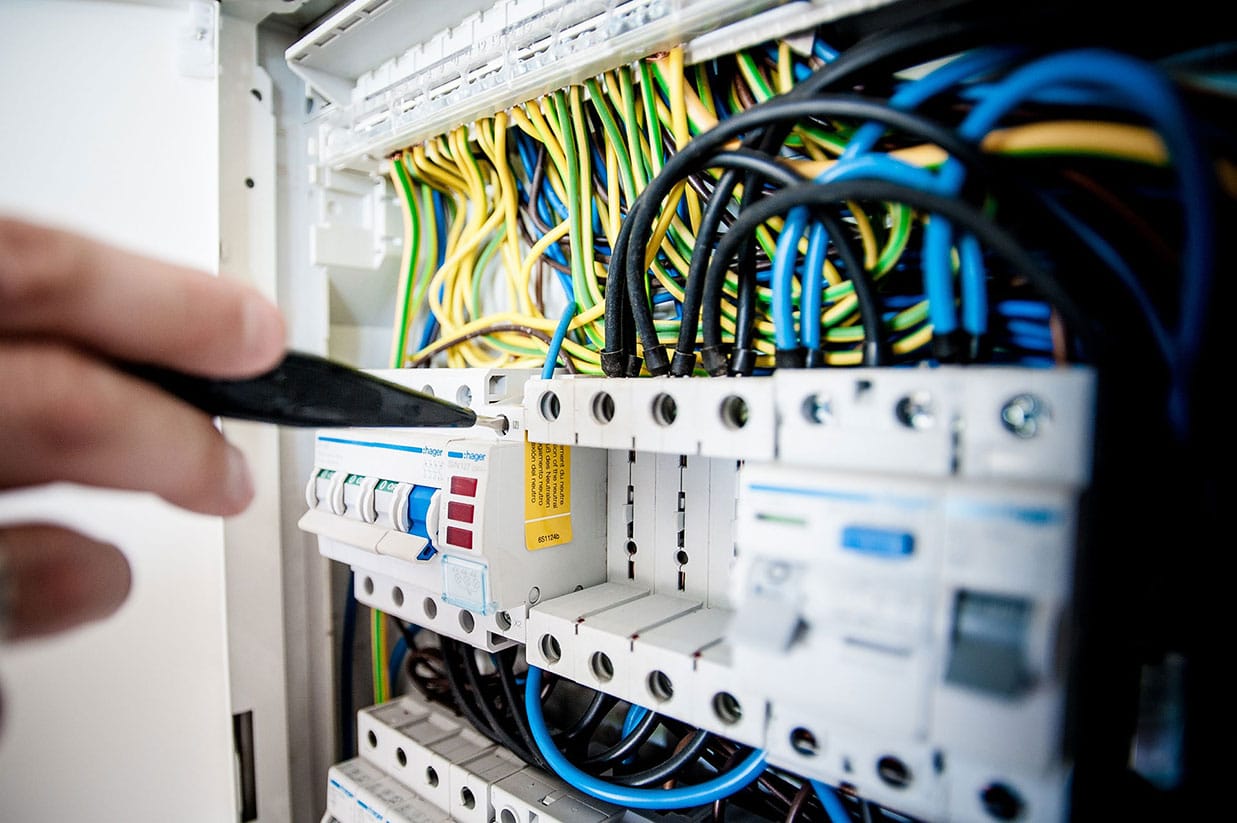

Wire Harness and Cable Assembly Manufacturing

Amphenol DC Electronics is a custom cable assembly and wire harness manufacturing company. We specialized in the design, engineering, and manufacturing of custom wire harnesses, cable assemblies, and integrated electronic mechanical devices (box builds). Established in 1979 and acquired by Amphenol in 2013, ADCE built a reputation of uncompromising quality, innovation, and delivery excellence that is second to none. As an Amphenol company, the foundation has been reinforced and expanded like never before. Servicing our diverse customers worldwide from our state of the art manufacturing facilities in Silicon Valley and Nogales, Mexico, ADCE is now a global wire harness and cable assembly leader with access to expertise and resources on six continents.

Our Services

Custom Cable Harnesses & Assemblies

For over 30 years, Amphenol DC Electronics has been focused on building custom cable and wire harness assemblies. This single focus gives us a level of experience and expertise that is hard to find anywhere else and enables our engineers to spot design flaws or manufacturability issues prior to production.

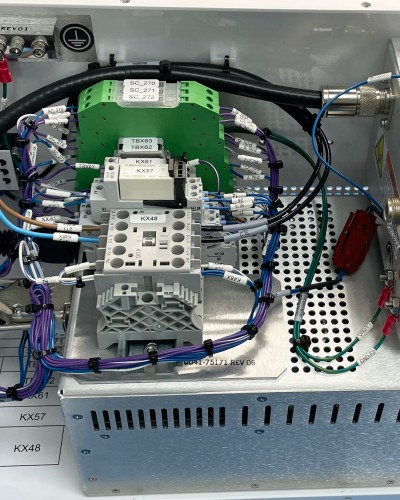

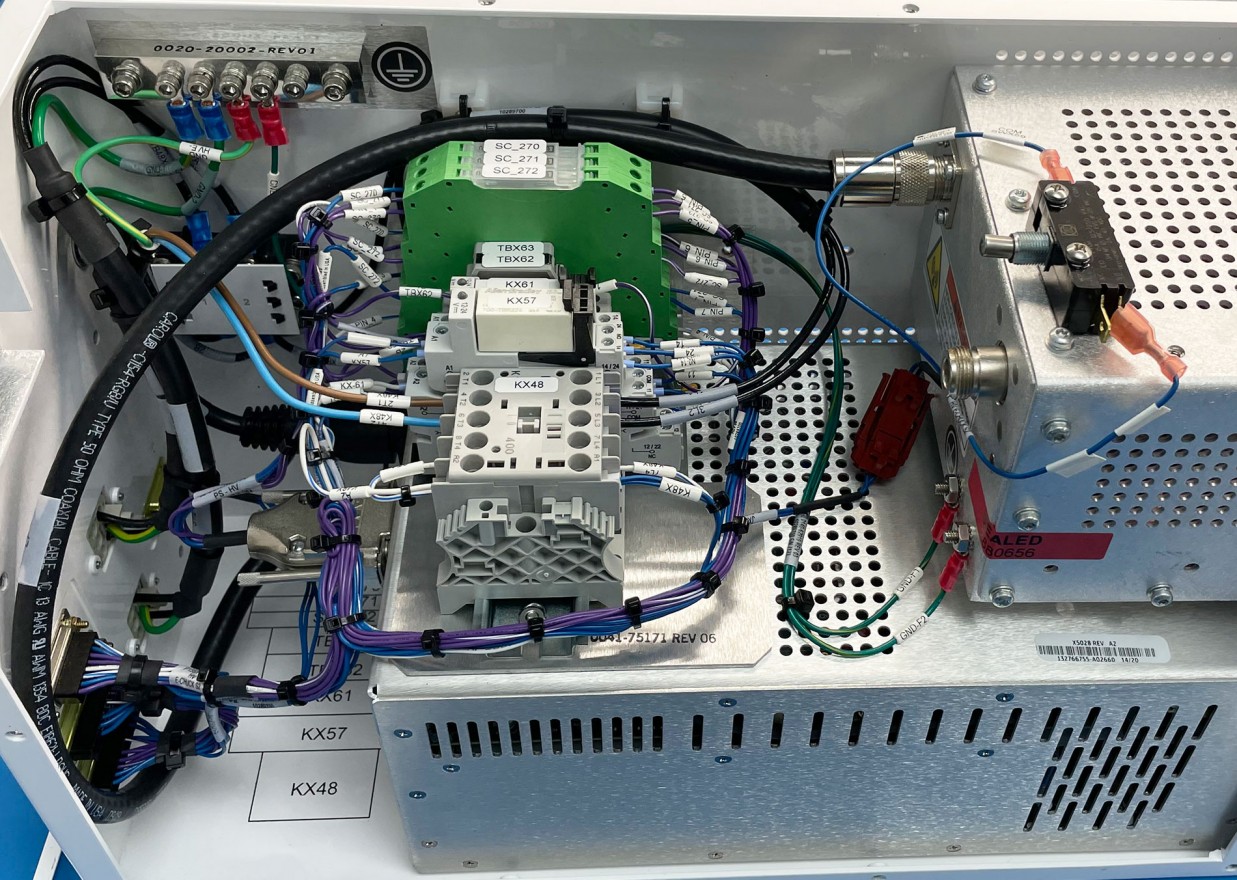

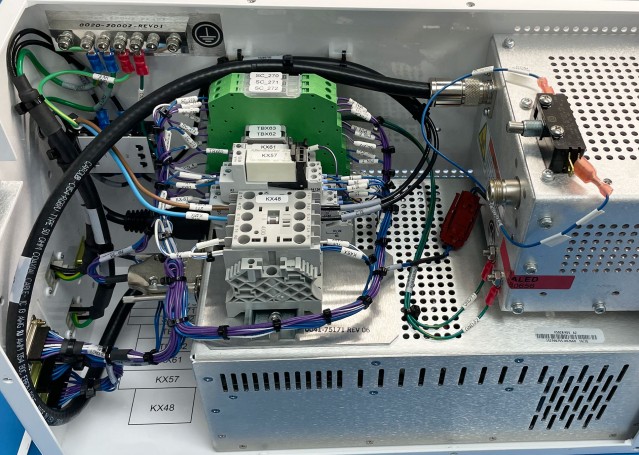

Integrated Electrical Mechanical Devices

Amphenol DC Electronics manufactures integrated electronic mechanical devices and custom box builds designed to offer optimum protection for your wire harnesses and cable assemblies. Box builds are effective in the number of purposes they can serve, from enclosing controls or electronics and connections to protecting them in a number of potentially hazardous settings.

Overmolded Cable Assemblies

Amphenol DC Electronics can build to print most custom overmolded cable assemblies designed for today’s sophisticated applications. Whether you are looking for overmolded cable assemblies that can withstand harsh or demanding environments or have performance parameters that must be met for your industry, the team at ADCE will make it possible.

Discrete Assemblies

Amphenol DC Electronics works with industry-leading suppliers that specialize in offering IPC-620:2016 Class III certified parts. With state-of-the-art manufacturing facilities and over 30 years of industry experience, we will work with you to develop the optimal wire assembly solution for your project.

Medical Device Cables

Amphenol DC Electronics has the experience and the ISO 13485:2016 certification standards to produce medical cable assemblies for a broad range of medical device manufacturers. From MRI scanning equipment to patient monitoring and surgical robotics, we work with leading manufacturers to produce cutting edge medical technology for a variety of applications.

Value Added Services

Amphenol DC Electronics holds to the principles of continual improvement at every stage of our process. Our in-house engineering and design liaison service enable build-to-print proficiency and the opportunity for increased efficiencies with manufacturability. We have applied lean manufacturing practices not just to the production floor, but to the way information and materials flow throughout our organization.

Industries Served

- ITAR

- SAM

- GDEP

- C-TPAT

- Overmolding for ruggedized assemblies

- Class 1000, 10,00 Clean Work Area

- Data Cables, RF Coax, Smart Cables

- IPC-620

- ISO 13485:2003

- Assemblies / cables for medical imaging machines (MRI and CT scan, X-ray equipment)

- Assemblies / cables for robotics and life support and medical laboratory equipment

- Specialized overmolding (special materials)

- UL508

- UL764

- IPC-620

- Tooling / Design / Prototyping

- Custom CAT5/6 cable assemblies

- IPC-620 Class III

- ISO 13485:2016

- Advanced Heavy Duty Overmolding

- Smart Cables

- Multi-Conductor Assemblies

- RF Coaxial Industry Application

Value Added Services & Integrated Processes for Electronic Assemblies

Custom In-House Tooling

Amphenol DC Electronics holds to the principles of continual improvement at every stage of our process. Our in-house engineering and design liaison service enable build-to-print proficiency and the opportunity for increased efficiencies with manufacturability.

Personalized Customer Support & Order Fulfillment

With such efficient systems, we can respond thoroughly to complex prototype development and specialized engineering needs while ongoing customer support and order fulfillment remain prompt and error-free. For the most accurate and up-to-the-minute shipping and delivery information, we have synced our shipping department with the order management systems our customers use.

CNC Produced Custom Molds

Amphenol DC Electronics has a fully equipped CNC machine shop on site that allows us to produce our own custom molds. Whether you are coming to us with a specified drawing or simply a sketch on a paper napkin, we can build to print. We have the capability to translate your concept into properly designed CAD drawings and deliver a prototype within a tight time frame.

Supply Chain Management

Amphenol DC Electronics has a mature global supply chain capability that allows us to work in a higher efficiency rate that increases output and decreases cost at the same time.

- MRP – Processed Daily

- Supplier Contract Pricing

- Competitive Sourcing Process

- Kanban Program

- Min/Max Control Levels

ISO Certifications, FDA Registration, & More

Proof that Amphenol DC Electronics delivers the highest quality lies in our certifications and registrations. We produce wire and harness cable assemblies for the most demanding industries. From medical device manufacturers to aerospace defense contractors, our process meets and even exceeds most manufacturing requirements, including:

- ISO 13485:2016

- IPC-620 Class III

- UL508 Certification

- FDA Registered

- CSA File Certification

- ITAR Registration

Cable Prototyping

Amphenol DC Electronics have the ability to take a project from rough concept to finished design schematics, prototype, and full-scale production. Our 30 years of experience building cable assemblies and a crack engineering liaison team enable us to provide reverse engineering assistance for even the most challenging projects. Through design liaison services and hands-on engineering support, we work closely with our customers to develop prototype designs fast and accurately.

Locations

Silicon Valley Headquarters

Located in San Jose, CA.

Our facility is 70,000 square feet, hosting approximately 300-plus deeply trained personnel with highly automated processes and capabilities.

Mexico Branch

Located in Nogales, Mexico.

This facility is 50,000 square feet, hosting 250+ deeply trained personnel. P&L wholly owned and controlled by ADCE.

Malaysia Branch

Located Penang, Malaysia

Green fielded an operation in Penang, Malaysia to support the APAC region. The facility is 40,000 square feet and is located in Batu Kawan Industrial Park.

ADCE Tulum

Located in Nogales, Mexico.

The facility is 40,000 square feet expandable to 80,000. Currently have 75+ deeply trained personnel.