Custom Cable Harnesses & Assemblies

Custom Cable Harnesses & Assembly Services

For over 30 years, Amphenol DC Electronics has been focused on building custom cable and wire harness assemblies. This single focus gives us a level of experience and expertise that is hard to find anywhere else and enables our engineers to spot design flaws or manufacturability issues prior to production. With a complete spectrum of materials, technology, and design options for OEMs needing wire harness assembly products, our customers continue to turn to us for their custom cable assembly needs. Our custom cable assembly manufacturing services include smart cable assembly, custom overmolds, semi-rigid coax cable, sub-miniature coax cabling, cable braiding, ruggedized assemblies, and fiber optic cables.

Amphenol DC Electronics, Inc. can provide the cabling needed for your custom cable assembly. Options include, but are not limited to:

- Flexible Cable

- High Density

- IDC

- MDR

- 1mm & 2mm

- PCMCIA

- Discrete SCSI I, II, III

- Circular

- Santoprene

- PVC

Amphenol DC Electronics’ design analysis and component spec checks are a standard part of our quoting process. We strive for the highest quality without sacrificing cost and efficiency. Amphenol DC Electronics is registered and certified to perform custom cable harness and assembly manufacturing to meet the following standards:

- ISO 13485:2016

- IPC-620 Class III

- UL508 Certification

- FDA Registered

- CSA File Certification

- ITAR Registration

Get started with your custom cable assembly order today!

Smart Cable Assembly & Circuit Integration

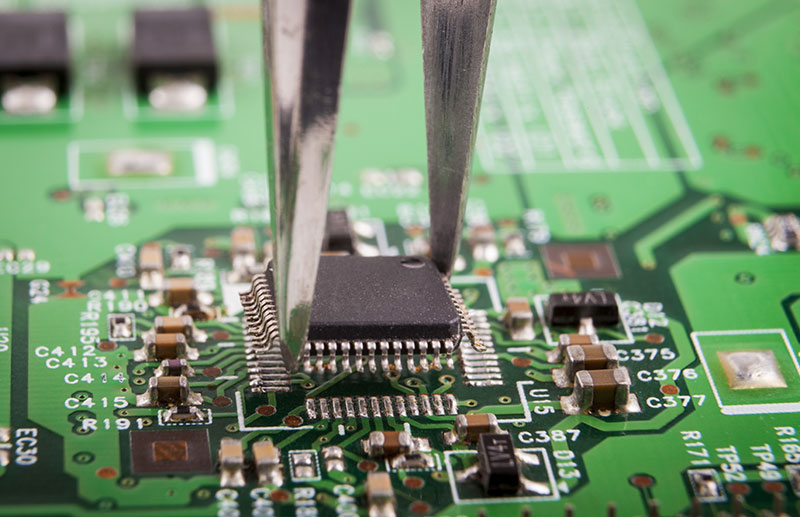

Amphenol DC Electronics offers a wide range of intelligent cables and smart cable assembly solutions for use in the sophisticated technology preferred by many industries. The evolution of electronics to smaller, lighter, and faster models has prompted the integration of circuitry into the cable assembly design. ADCE provides design and engineering facilitation and manufactures custom overmolded cable assemblies that make it feasible to realize successful connections within the miniaturized electronics that many companies are leaning towards.

Applications of Smart Cables with Printed Circuit Boards

Smart or intelligent cables incorporate printed circuit boards (PCBs) within a custom overmold for optimal connectivity. Amphenol DC Electronics’ smart cables have been used to help companies across a number of industries to make great strides in cable assembly design innovation. Companies within the military, aerospace, medical, and robotics industries have turned to the experienced team at ADCE for smart cable technology. ADCE offers smart cable solutions for sensors, switches, bio-medical devices, SMT/ML PCBs, and a number of other electronics applications.

High-Volume Ruggedized Custom Cable Assemblies

Amphenol DC Electronics has custom ruggedized cable and harness assembly options that provide superior performance in the most demanding environments. Our overmolded cable assemblies are manufactured to survive a variety of conditions, from intense UV exposure to heavy-duty manufacturing operations. We are proud to provide ruggedized custom cable assembly products for use in a number of industry applications, including those for agriculture, solar, and industrial manufacturing.

With decades of experience in providing ruggedized cable and harness assembly products to meet a wide range of specifications, ADCE has developed an extensive overmold tooling library. This resource makes it possible to provide cable and harness solutions for many overmolded cable assembly requests with quick turnaround and cost savings. ADCE also employs a number of quality and efficiency initiatives throughout our custom cable assembly processes, including Six Sigma, process mapping, and risk analysis. We are working to achieve our Six-Sigma Black Belt certification, Lean Manufacturing, 5S, and 10 Keys process control systems.

Cable Braiding

Amphenol DC Electronics ensures the success of your interconnectivity projects with custom cable harnesses that utilize the latest cable braiding technology. With multiple 24 and 32 Carriage New England Butt Braiders in our California cable harness manufacturing facility, we can provide cable braiding solutions for even the most challenging projects. New England Butt Braiders are the preferred equipment choice for rapid and consistent cable braiding of custom wire harnesses. From ruggedized assemblies to those requiring specialized materials or strength-to-weight ratios, your build to print cable harnesses are possible with this cable braiding technology.

Case Studies

The Acquisition

This is a perfect example of how DC Electronics works in close partnership to help customers achieve their broader objectives.

Cable Reproduction

When we’re asked to copy something, we go one better.

Industrial | Solar

One of the largest solar start-ups in the Silicon Valley asked DC Electronics to help develop a harness for their solar panels.