San Jose, California, January 2, 2012 – DC Electronics today announced it has met all the requirements and passed inspection from an independent certifier to qualify for ISO13485 Class III certification. The company will receive its Registration Certificate by January 31, 2012.

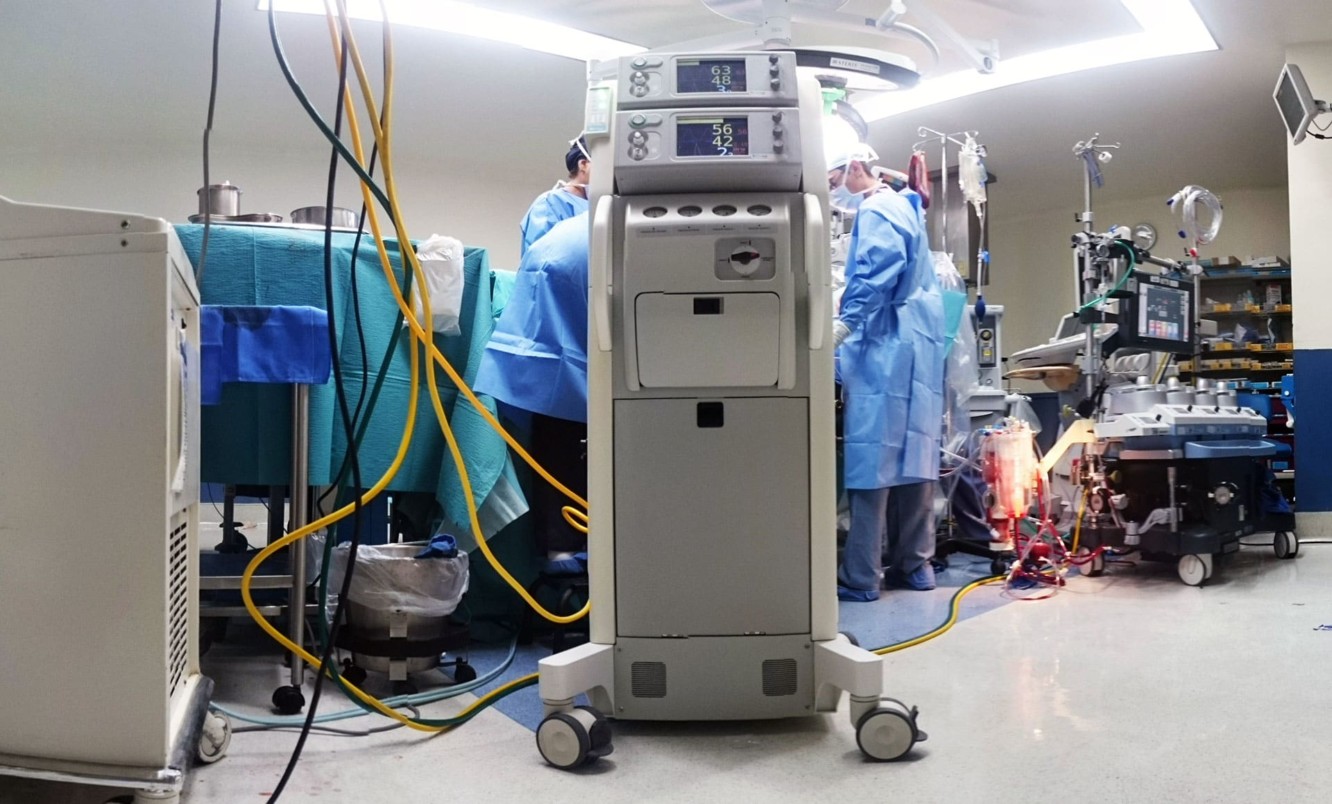

The ISO13485 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and government regulatory requirements. Of the three FDA regulatory classifications of medical devices, Class III is the most stringent, as it covers devices which support or sustain human life.

The primary objective of ISO 13485 is to facilitate harmonized medical device regulatory requirements for quality management systems. As a result, it includes some particular requirements for medical devices and excludes some of the requirements of ISO 9001 (a family of international quality management standards) that are not appropriate as medical device regulatory requirements. Because of these exclusions, only organizations whose quality management systems conform to all the requirements of ISO 9001 can claim compliance with European standards. DC Electronics is proud to conform fully to ISO 9001:2008 in order to meet maximum international quality requirements.

“This certification is really a testament to who we are and how we work,” says company president, Dave Cianciulli. He adds, “It recognizes the strength and depth of the systems and people we’ve put in place over the last thirty years.”

This process is very critical to DC’s medical customers, whose device cable assemblies are required to be compliant to the FDA.

“With this new medical cable certification comes more traceability, responsibility, and accountability,” Director of Quality, Leonard Martinez, says, “We’ve upgraded our skill sets across the board. Workmanship and soldering techniques are now Class 3. Overlapping Six Sigma processes ensure that defect detection happens fast. From process mapping to risk analysis, the new systems really increase our capabilities.”

About DC Electronics

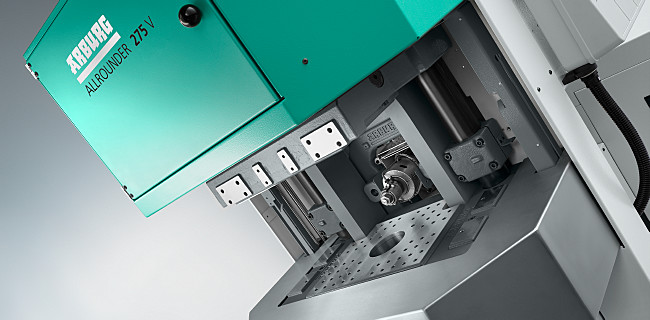

DC Electronics provides custom cable manufacturing and engineering for aerospace, agriculture, construction, industrial manufacturing, medical, military, nuclear, semiconductor, telecom, transportation, underwater and photovoltaic industries.

Founded in 1979 by former Hughes Aircraft executive, David Cianciulli, Sr., and now run by David Cianciulli, Jr., this family-owned company has a stellar reputation for innovation, consistent high quality, and top-level service for demanding customers.